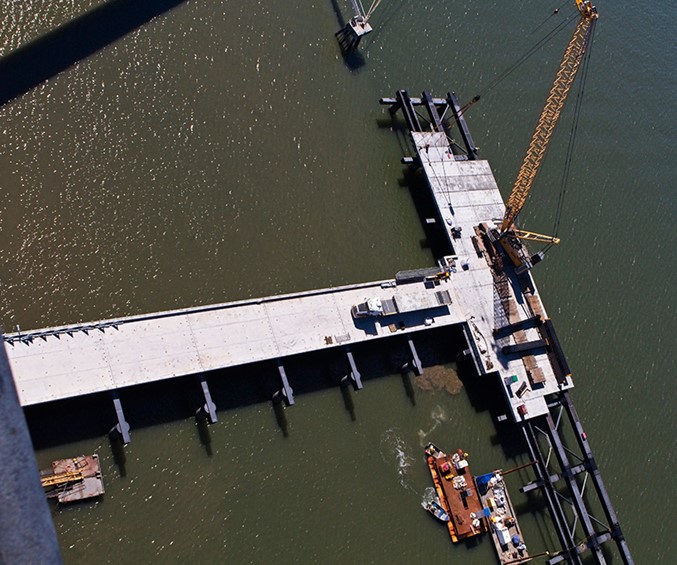

A new Wharf on the Brisbane River at Pinkenba, Queensland was opened in July 2018. It was built to service the direct berthing of cement clinker ships that carry 35,000 tonnes cargo, as well as other general cargo ships.

The wharf’s construction features a new and innovative approach to building materials and delivers significant advancements in both environmental and engineering performance.

The wharf’s deck is comprised of 191 prefabricated panels that span between 8 and 12 metres over steel headstock beams. The panels are a unique hybrid structural system developed over many years by Wagners R&D division initially for use on pedestrian and road bridges. The system has been adapted and further developed for the challenging conditions of a marine wharf structure.

Each panel consists of:

The EFC® mix was developed to suit placement through heavily congested reinforcing layers and achieve the design strength requirements:

High flexural strength in comparison to conventional concrete is a benefit of EFC® that was able to be used in the design of the deck panels. The mix also satisfied the demand of high production precast by attaining the minimum 20 MPa lift strength in typically 15 hours without any artificial heating.

The FRP reinforcement for the wharf deck units were designed by i-cubed engineers in accordance with Canadian Standard CSA S806 because at this time there is no Australian Standard for FRP rebar.

The hybrid deck superstructure represents a new approach using high technology building materials to deliver efficient, low maintenance and low CO2 emission engineering structures. The application of these materials in an innovative engineering design has delivered a wharf structure that has performed well against the client’s key criteria of economy, fit for purpose, speed of construction and reducing the environmental impact.

Wagners and Wagner Corporation

Pinkenba, Queensland

CFT

EFC

Precast Concrete

Official opening photo courtesy of Simone D Photography

Aerial shots courtesy of Russell Genrich Photographer